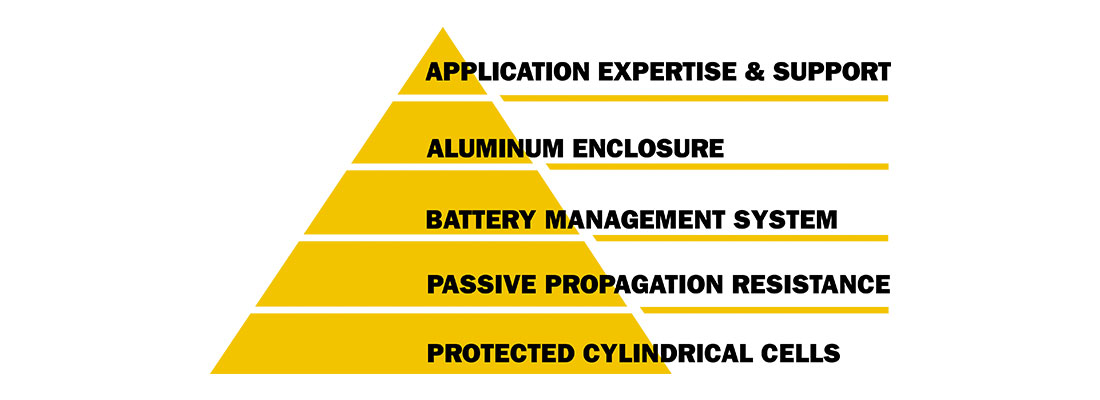

Battery Safety: A Hierarchy of Needs

Battery adoption for outdoor power equipment is on a growth trajectory and many who are just beginning to explore electrification opportunities will have a lot of questions. From safety to reliable performance, we’re here to explain how Vanguard® lithium-ion commercial battery safety features help equipment operators get their jobs done with power they can trust.

There are five safety needs we placed in a hierarchy that must be satisfied from the bottom of the pyramid up so that a Vanguard lithium-ion battery can perform to its full potential:

5. Power Application Center (PAC): Our world-renowned PAC empowers dependable testing and performance for customers and their equipment goals and needs.

4. Diecast Aluminum Enclosure: A newly designed, sleek enclosure gives our batteries a professional look and maximum protection.

3. Battery Management System (BMS): The BMS monitors and controls current and temperature thus protecting the battery.

2. Passive Propagation Resistance (PPR): The design of the battery pack is heavily focused on PPR so if one cell fails, it will not spread to adjacent cells.

1. Protected Cylindrical Cells: Our wire-bonded cylindrical cells offer the best variety of safety and performance.

Now that you’ve seen this hierarchy, let’s dive into each hierarchical need in order of importance and why it is essential to a reliable and safer battery.

Without Good Cells, You Won’t Have A High-Performing Battery

It’s true. Cells are the main component of a battery making it the foundation of a Vanguard lithium-ion battery. We use cylindrical cells since they offer the benefits and reliability that OEMs and end-users need. Each cell in our modules is fused to prevent thermal events by interrupting the electrical path between each cell if necessary. This wire-bonding technology protects and connects each individual cell – another safety feature on top of our rigorous cell qualification process. We constantly look at cell options and chemistries and stay current on trends to assure we’re bringing the best battery products to the market and elevating the standards of battery-powered equipment.

Safety By Design

Next in the hierarchy is a safety feature that Vanguard battery engineers leveraged to be uniquely applied throughout all Vanguard commercial batteries: passive propagation resistance (PPR). In PPR, cells are evenly spaced out so that if one has a failure, it will not spread to any neighboring cells. In multiple-tier packs, there is a plate preventing cells from affecting those above or below them as well. This truly elevates the quality of Vanguard batteries making it the second most important feature that relates to the expert engineering behind our battery packs.

Passive propagation resistance: Prevents a chain reaction if one cell goes bad.

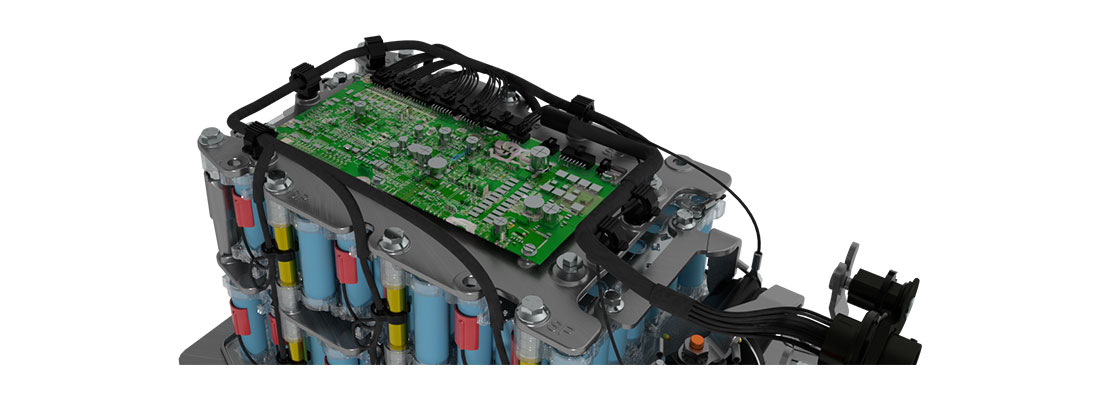

Intelligent By Design

The Battery Management System (BMS) is what we call the brain of the battery. This advanced circuit board monitors every Cell Module Assembly – a block of cells we assemble to build and configure packs – allowing us to capture issues fast. As an example, the BMS tracks temperature and voltage and if either reaches an unsafe operating state, the pack disconnects itself from the equipment. Furthermore, when the battery is charging, the BMS controls when charging should stop. It’s very common for rechargeable batteries to be mischarged due to low knowledge of healthy charging practices. Regulated charging prevents mischarge along with thermal events.

Look Good, Feel Good

What’s on the outside is just as important as what’s on the inside. With many years of diecasting experience on the internal combustion engine side, our team designed an aluminum diecast outer shell that protects the battery from virtually everything around it. Water, dust, dirt, and debris cannot get inside the battery, which is critical to ensure for OEMs and operators. Not only is this new enclosure of Vanguard batteries more durable, but it’s also more professional looking and higher grade for commercial use.

From left to right: Fi3.5kWh, Si1.5kWh, Fi7.0kWh (Tall), Fi7.0kWh (Long)

Empowering A Culture Of Top-Notch Performance

Last but not least in this hierarchy is our world-renowned Power Application Center (PAC) with locations in the United States, Germany, China, Japan, and Australia. Our PAC teams around the world identify and perform the appropriate application tests, select and test power sources for the application, support new product development, and troubleshoot issues that may arise in the field. All of this knowledge held by one team help Vanguard batteries (and you) reach their full potential.

A Vanguard Commercial Battery on a shaker table in Briggs & Stratton’s Noise, Vibration, and Harshness (NVH) Lab located in Wauwatosa, WI.

Recapping The Hierarchy

If you are at a crossroads in choosing the right type of battery or are ready to start your electrification journey but don’t have much knowledge, then know that our battery’s hierarchy of safety needs is important to understand.

First, we make sure that we have quality cells, then protect those cells with a PPR-based design. Next, giving our battery the ability to self-regulate helps everyone feel confident in the work it can do. Additionally, the sharp-looking aluminum diecast enclosure protects the battery from everyday wear and tear. Finally, once all of these levels of safety have been achieved, our PAC does everything it can to help Vanguard commercial batteries, and you, reach their full potential and chase the endless electrification opportunities on the horizon.

Need to get in touch with our battery experts? Contact us to learn more.