Servicing The Valves

What are valves?

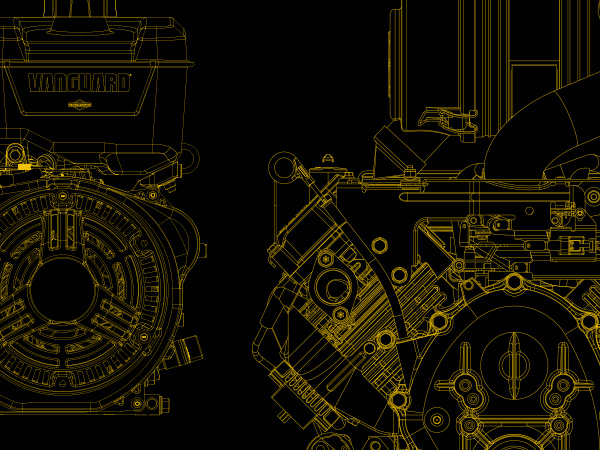

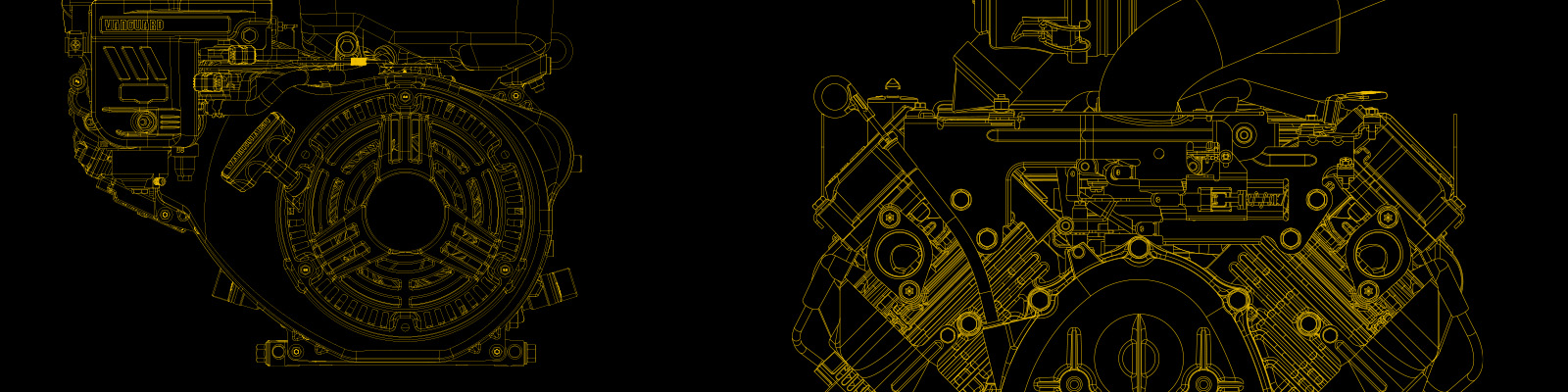

All 4-stroke engines have intake and exhaust valves for each cylinder. These valves are used to control the flow of air and fuel into a cylinder as well as exhaust out of a cylinder. Modern engines feature overhead valve (OHV) technology which places the valves directly above the piston within the cylinder head. This design provides the best efficiency as well as the best thermal management properties for an air cooled engine.

Does my engine's valves need regular service?

The short answer is no. Engines with OHV combined with modern materials used in the valvetrain make for a significant reduction in service requirements. Regular service of OLDER designs would include decarbonizing the combustion chamber, resurfacing the valve sealing surfaces and possible valve guide replacement.

Adjustments

Most engines will require a valve lash adjustment at a recommended interval. For engines that accumulate many hours of operation, adjustments may be more frequently needed. It’s always best to consult your Operator's Manual for the recommended check/adjust intervals.

Commercial engines that run for very long periods of time usually will see recommendations of check/adjust every 250 hours of operation or if performance problems are noted. Refer to our Valve Lash Adjustment video for instructions on how to perform a valve lash adjustment that apply to Vanguard Small Block, BIG BLOCK™ and 810cc V-Twin engine lines.

Applications that would be considered for long operational use are:

- Generators

- Commercial Mowers

- Water Pumps

- Construction Equipment

- Rental Equipment

MORE INFORMATION

Have more questions? Ask our new tool, Briggs & Stratton Assist for fast and accurate answers.

LOCATE A DEALER

Finding the right dealer is key to getting the right help. Our dealers are certified and specialize in selling or servicing our different product types.