Vanguard® Single Cylinder Engines

INCREASED PRODUCTIVITY BY DESIGN.

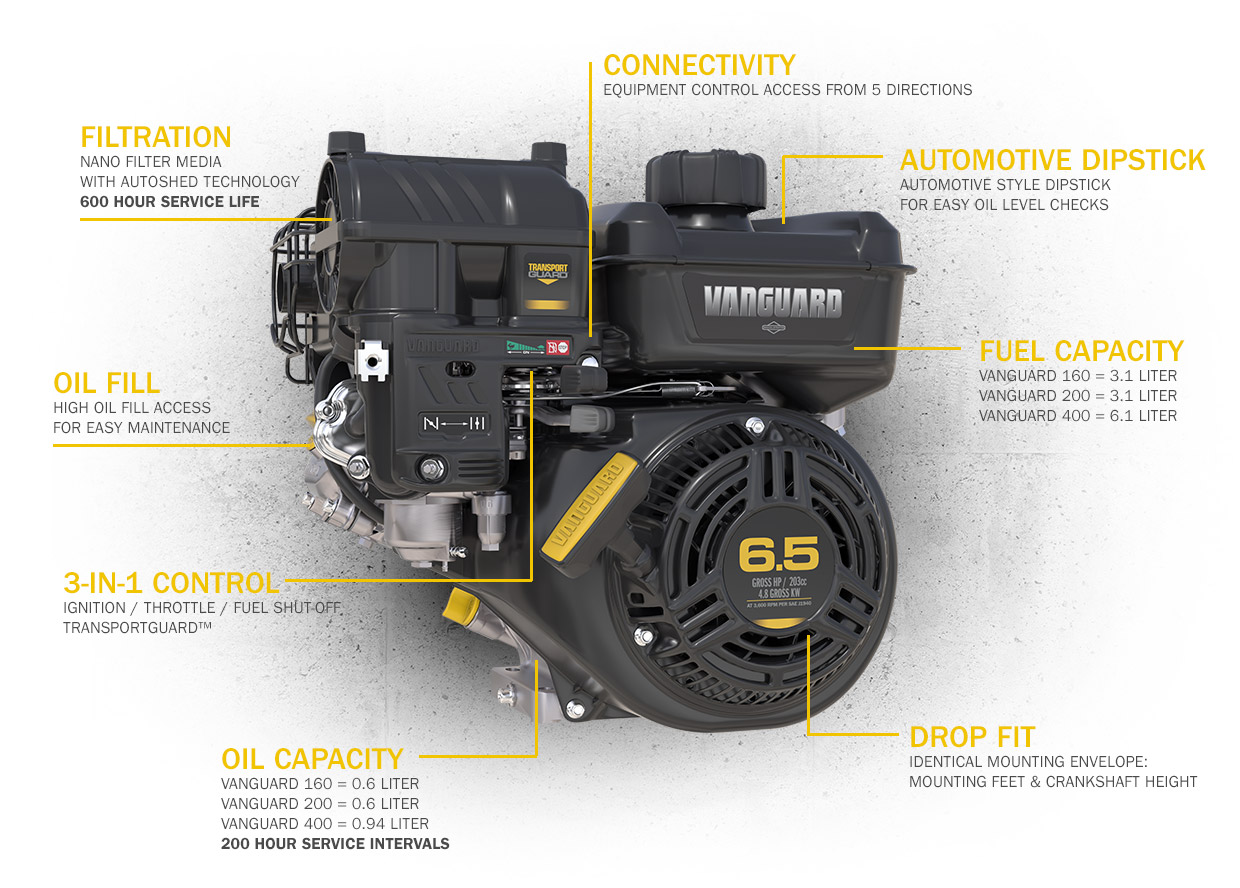

A ground-up designed OHV engine application engineered to deliver durable performance with lower TCO, easier starting, lower noise and vibration, and a reduced carbon footprint.

The commercial grade Vanguard engines feature a cast-iron sleeve, dual ball bearings and a forged crankshaft which are all optimized and precision balanced. All of this leads to a more durable and reliable power solution for increased productivity and improved user comfort.

Increased uptime. Reduced maintenance.

THIS IS PRODUCTIVITY DEFINED.

VANGUARD ENGINE RANGE

*All power levels are stated gross kW at 3600 rpm per SAE J1940 as rated by Briggs & Stratton

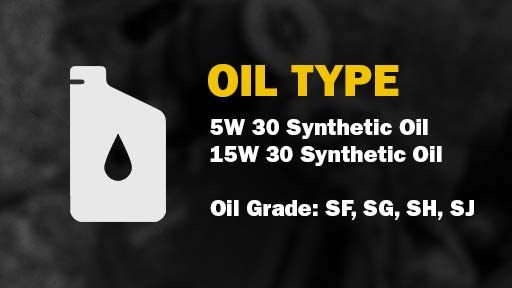

Keeping your Vanguard-powered fleet in optimum condition.

Download your Vanguard engine illustrated parts list.

Vanguard engine parts are available through the most comprehensive global service and support network in the industry. Order parts via your distributor or find your closest Vanguard dealer.

We’re also a proud member of the SmartEquip network, making it easier

than ever to ensure that the rental locations are getting the most out of

their Vanguard-powered equipment.

Maintenance Schedule

| First 5 Hours |

|

| Every 8 Hours or Daily |

|

| Every 100 Hours or Annually |

|

| Every 200 Hours or Annually |

|

| Every 600 Hours or every 3 Years |

|

| Annually |

|

1 In dusty conditions or when airborne debris is present, clean more often.

2 Not required unless engine performance problems are noted.

TransportGuard™. Exclusive to Vanguard®

Rental equipment returned to rental depots often has the fuel valve left open. Failure to shut off the fuel supply before equipment transportation can lead to fuel and oil dilution, resulting in unnecessary and costly oil changes. In addition, these unnecessary oil changes increase your organization's CO2 footprint. TransportGuard™ exclusive to Vanguard eliminates this problem.

The 3-in-1 lever shuts off the fuel supply automatically when the operator turns off the engine ignition.

Click here to see how TransportGuard™ works.

Problem solved.

Vanguard 200 vs. industry standard*

* 200cc equivalent engine

** Savings are based on 2000 hours of operation, using original engine manufacturer's oil as well as air filters, and calculated based on distributor market pricing to rental.

CALCULATE TCO SAVINGS BY ENGINE MODEL

Find out how much money you can save on oil and air filtration, when you choose to power your equipment with one of the Vanguard single cylinder engines.

REDUCED ENVIRONMENTAL IMPACT

50% REDUCTION

An independent life cycle analysis by the industry leading Climate Neutral Group demonstrated that the new Vanguard single cylinder engines reduce the environmental impact of oil and maintenance parts used during the equipment working life by over 50%*.

Oil is the dominent contributor to the environmental impact of an engine accounting for over 80% of the Global Warming Potential during maintenance.

Find out more about the Climate Neutral Group.

*Reduced environmental impact or global warming potential (GWP) of maintenance parts for the new Vanguard 200 & 400 engines compared to respective predecessors, measured in kg CO2 eq. per Climate Neutral Group study.

CALCULATE YOUR LIFETIME ENVIRONMENTAL IMPACT REDUCTION* WHEN YOU CHOOSE VANGUARD® TO POWER YOUR FLEET.

*Related to quantity of oil usage & recycling based on 200 hour oil change intervals for Vanguard vs. 100 hour intervals for the leading competitors.

View Vanguard 160, Vanguard 200 and Vanguard 400 product pages for more detailed information and available options.

SUPERIOR SUPPORT SOLUTIONS

Vanguard training programs are designed to equip your teams with the knowledge and skills to keep your fleet up and running – maximizing uptime and productivity.

We offer flexible training at our purpose built training facilities across Europe, 24/7 e-learning via our PowerPortal, as well as bespoke onsite training upon request.