INDEPENDENT ANALYSIS SHOWS: VANGUARD® ENGINES REDUCE TCO AND ENVIRONMENTAL IMPACT OF RENTAL FLEETS

Freienbach Switzerland, 12 October 2020 – Vanguard’s new 200 and 400 engines are known to require significantly less maintenance than their equivalent predecessors, resulting in a lower TCO. Now, a recent analysis by Dutch Climate Neutral Group (CNG) and Vanguard shows that they also boast a ~53% reduced environmental impact during their lifetime. The results are based on an independent lifecycle analysis* measuring the environmental impact of the engines’ maintenance during their usage phase. The reduction, measured in kg CO2 eq., is a benefit of their extended maintenance intervals.

Extended maintenance intervals reduce environmental impact

The analysis showed that, of all maintenance activities, oil usage is the largest contributor to an engine’s environmental impact, accounting for over 80% of its Global Warming Potential (GWP).

The study revealed that the 200 and 400 engines require significantly less oil over the engine life, resulting in a lower and superior greenhouse gas (GHG) emissions profile during the maintenance stage of their lifecycle. And with the extended, 200-hour oil maintenance intervals – double# the industry standard – the environmental impact of an entire rental fleet powered by these new Vanguard engines is significantly reduced.

Boels Rental, the second largest rental company in Europe, uses Vanguard engines to power its fleet, and underscores these benefits. Guy Cremer, Director of Fleet Operations at Boels Rental, explains: “The new generation of Vanguard single-cylinder engines offers many game-changing improvements. The engines allow us to cut our equipment service intervals almost by half, and reduce our oil waste and recycling, thus decreasing the environmental impact of our fleet.”

Higher productivity and lower TCO

Optimizing extended service intervals for equipment is a key best practice for any fleet manager. Performing too many or too few oil changes during the usage phase will negatively impact equipment uptime and total cost of ownership (TCO). Paul Bramhall, Director Marketing EMEA for Briggs & Stratton, explains: “Companies in the rental industry pride themselves on providing a more sustainable business model. Extended maintenance intervals increase equipment uptime while reducing environmental impact. This positively impacts the fleet’s TCO and the company’s bottom line.”

Reduction is better than recycling

While recycling is seen as an ideal method for managing the end-of-life process for any given product, the most effective way to decrease waste is to reduce consumption. With Vanguard’s extended service intervals, the engines naturally require fewer maintenance parts and oil changes during their working life.

Martijn in’ t Veld, Carbon Strategy Advisor of the Climate Neutral Group, comments: “Reducing an organization’s need for oil and spare parts while maintaining the optimal performance of the engines is a step in the right direction. While the environmental impact of one engine with extended service intervals may be small, the combined effect over an entire fleet or industry has the potential to significantly reduce the impact on our environment.”

Paul Bramhall concludes: “Vanguard aims to deliver market-driven innovation based on the voice of customer. As a member of the European Rental Association, we furthermore strive to deliver power solutions that address the very specific needs of this market. Following the ERA convention in Madrid last year, we approached the Climate Neutral Group to understand the environmental impact of routine engine maintenance during the usage phase of the equipment’s lifecycle. With extended service intervals, the new Vanguard engines deliver what the market is asking for in terms of reduced environmental impact, increased productivity and lower total cost of ownership.”

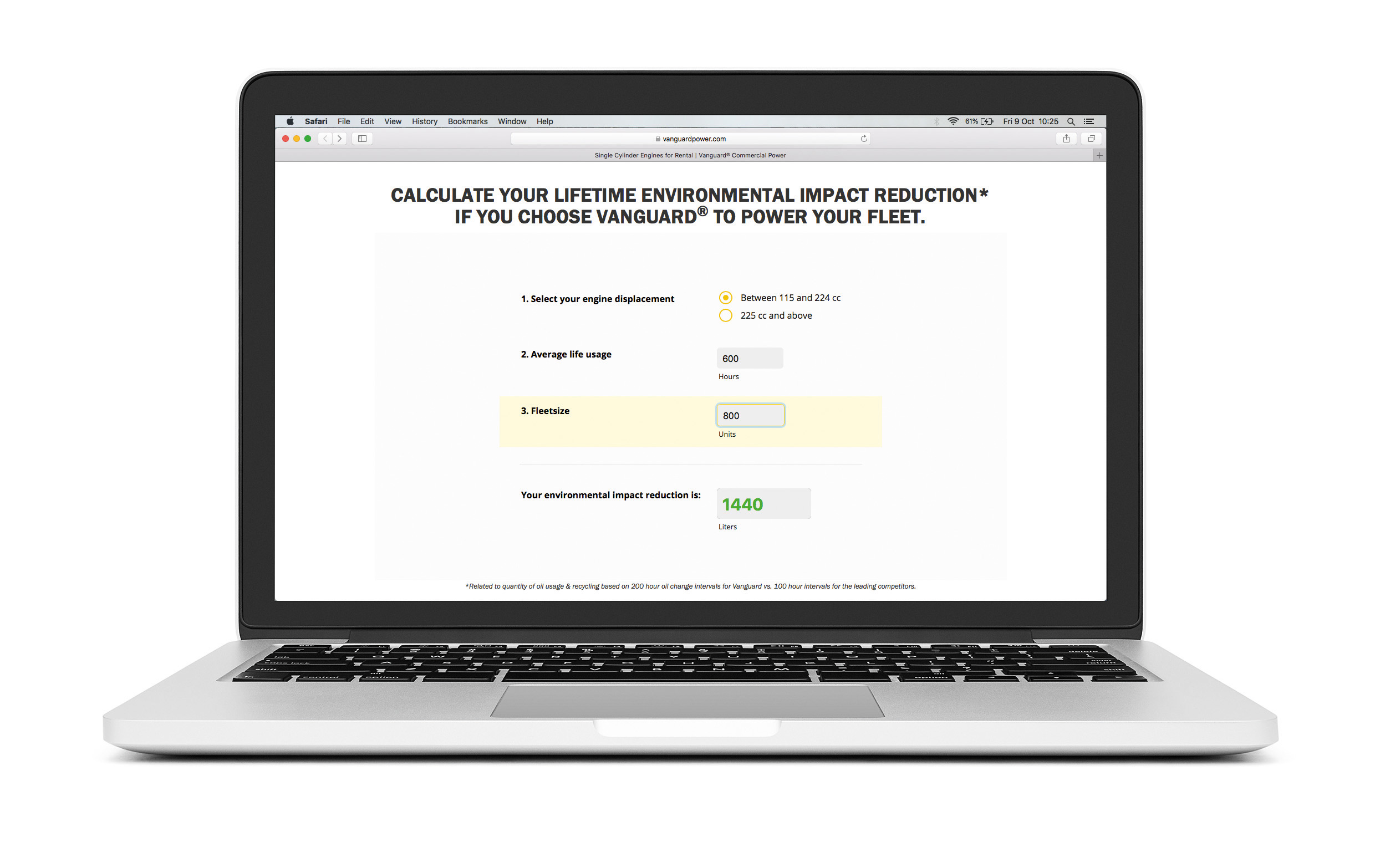

Free online TCO and environmental impact calculators

Fleet owners can calculate their fleet’s environmental impact reduction related to oil usage and its total cost of ownership on the Vanguard website via this link: Environmental Impact Calculator

*In accordance with ISO 14040 and ISO 14044 section 6.1 requirements.

#200-hour oil service intervals vs 100-hour oil service intervals of predecessors and the leading competition

Contact:

Hester Regoort, Two Rivers Marketing, +32 3 298 4948, hesterr@2rm.com

Paul Bramhall, Briggs & Stratton, +41 55 415 1254, bramhall.paul@basco.com

About Briggs & Stratton, LLC:

Briggs & Stratton, LLC, headquartered in Milwaukee, Wisconsin, is focused on providing power to get work done and make people's lives better. Briggs & Stratton is the world's largest producer of gasoline engines for outdoor power equipment, and is a leading designer, manufacturer and marketer of power generation, pressure washer, lawn and garden, turf care and job site products through its Briggs & Stratton®, Simplicity®, Snapper®, Ferris®, Vanguard®, Allmand®, Billy Goat®, Murray®, Branco®, and Victa® brands. Briggs & Stratton products are designed, manufactured, marketed and serviced in over 100 countries on six continents.