WHY VANGUARD

Our mission is to help professionals to get work done by applying power to their unique commercial applications. For more than 35 years, we have partnered with our customers to conquer challenges and develop innovative products. And we don’t simply provide components. Backed by Briggs & Stratton, we support our customers in applying lithium-ion and petrol power throughout the entire integration process, from development to serial production to after sales and training support.

For a tough long-lasting commercial grade power solution, look to Vanguard.

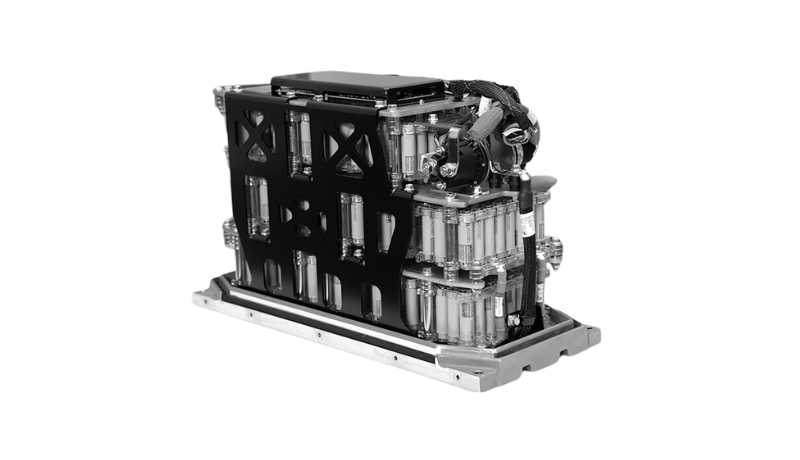

Our commitment to provide commercial grade power solutions for each unique customer sets us apart from the competition. Whether it is for industrial, recreational, or commercial use, we have the expertise to meet your power needs efficiently and effectively. Our engines and batteries not only reduce total cost of ownership but also prioritize environmental sustainability and meet today’s strict regulations for professional applications.

Vanguard power solutions have one purpose - to make your job easier.

Here is the solid basement of game-changing technology, making our products the number one choice when it comes to the powerful heart of your machines.

In collaboration with either our dedicated Vanguard power application experts or professional technology partners we offer top services and support to seamlessly integrate our engines and batteries into your applications.

Learn more about our products tailored to meet your specific requirements.

FOLLOW US TO STAY UP TO DATE